Home » industrial water »

industrial water

MPW’s Mike Morosko (foreground), Kyle Dillon (back left) and Larry Lee (back right) construct control panels in the Technology Center.

MPW Industrial Services earned a certification from Electrical Testing Laboratories (ETL) to build industrial control panels on December 27. MPW is now authorized to fabricate ETL-standard panels intended for general use. MPW’s Panel Shop

…

Read MoreJustin Pierce

As part of our regular Staff Profile Series, we recently interviewed Justin Pierce, Director of Engineering & Manufacturing at MPW Industrial Services. Having worked with the MPW team his entire career, Justin has been a key player in advancing the company’s engineering department.

How did you get your start with MPW?

…

Read More

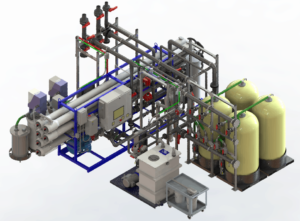

MPW’s Reverse Osmosis-Electrodeionization (RO-E) System is a convenient production solution for removing dissolved solids, total organic carbon (TOC) and other colloidal contaminants in a conveniently smaller footprint than traditional units.

The system is operable in either single- or double-pass mode, with nominal flow

…

Read MorePort Arthur Service Center. Port Arthur, Texas. Industrial Water Division.

Discuss your branch’s dedication to safety.

One of our daily reminders during our shift change meetings always includes the phrase “safety, quality, production.” Our belief is if we don’t do our job safely, no amount of quality or production can make up for an injured co-worker.

…

Read MoreMPW’s 15- and 30-cubic-foot ion exchange vessels provide customized systems to meet your specific flow rate and quality requirements. Systems can be provided in a variety of configurations from a single-vessel system up to dual-train, multi-vessel designs. Each system includes interconnecting hoses with optional

…

Read More“Rod was a key driver in the growth and maturity of the Industrial Water Division. He helped take MPW from a mobile DI trailer company to a full-service water treatment company by selling a number of very large baseload water systems.” — Jared Black

Rod Reston, Senior Business Development Manager for MPW’s Industrial Water Division,

…

Read MoreMPW’s Mobile Ion Exchange Resin Transfer (MIERT) trailer is capable of transporting both regenerated and exhausted resin with volume capacity of 1,500 cubic feet. There are four compartments each equipped to receive air or water pressure (or both) to sluice and move the resin.

…

Read MoreOn April 5, MPW officially broke ground for a 30,000-square-foot industrial water regeneration plant in Yuma, Ariz.

MPW’s site contractor Pilkington Commercial Company hosted the ceremony and in attendance were MPW President Jared Black, Director of Plant Services Jeff Thornton, Senior Mechanical Engineer Brian Charles and Brand Supervisor Ryan Cullins.

The new

…

Read More