Home » Industrial Water Media » Industrial Water Success Stories

Industrial Water Success Stories

MPW Allows for Swift Recovery After Power Loss

On a cold winter’s day, during active operations at a peak demand period, a critical incident occurred at an MPW water treatment system providing demineralized water to a power plant when a site contractor accidentally severed the power feed conduit while clearing snow. This resulted in a complete loss of 480V power, causing the MPW

…

Read MoreMobile UF/RO System Averts Wastewater Pond Overflow

A coal-fired power plant in Northwest Colorado faced a critical wastewater management issue. The facility’s large industrial water retention pond was dangerously close to overflowing, posing an imminent risk of an uncontained spill. The plant had resorted to stacking sandbags as a temporary barrier to raise the pond’s edges.

However, this was insufficient for long-term

…

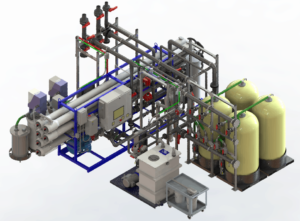

Read MoreMPW Industrial Water Completed Record-Breaking Project

Water Is flowing through a Delaware refinery following completion of a massive MPW customized Build-Own-Operate-Maintain (BOOM) System with multiple equipment units, producing all of the site’s process water. Industrial Water General Manager Tim Dondero said technicians worked through holidays to meet a tight deadline. “It’s a bigger project than we usually do,” Dondero said. “We

…

Read MoreMPW solves frequent CIP issues and improves quality for Ohio power company

View Full Case StudyDownload Problem

Low temperatures and water with high levels of phosphorous salts (alum) combined to gum-up the works for a Northern Ohio power plant, forcing ongoing clean-ups and production slowdowns.

In 2018, the assessment of water sup- plied from the local water supply was inaccurate

…

Read MoreThorough investigation, application of specialized equipment key to selenium removal. Problem

A former coal-fired power plant in the Northeastern U.S. had converted to a natural gas source. However, due to stringent EPA mandates, its remaining coal ash ponds, the byproduct of decades

…

Read MoreiWWD: Emergency Response Reverse Osmosis & Deionization Trailers

Mobile Deionization Demineralization (DI) trailer

When a Louisiana chemical plant suffered a site-wide blackout, plant personnel learned they would have to bring each power-generation unit, and its corresponding water filtration system, back on-line individually. Facility workers quickly returned the onsite demineralization system to functional status, but it was receiving almost zero condensate return.

To re-establish

…

Read MoreQuick rebed turnaround, safety measures satisfy customer. Problem

A Midwestern soft drink plant over-pressurized its No. 2 softener tank, damaging the internal tank laterals and rendering the tank useless until it could be repaired.

While tank No. 2 was out of service,

…

Read MoreProblem

Not satisfied with the variable cost of city water and the additional sewer charge associated with disposal of wastewater, managers at a Michigan oil refinery sought to restructure its water system by incorporating reverse osmosis (RO) technology. Plant personnel determined that reusing process wastewater

…

Read MoreFiltration units deployed for same-day purification

Problem

A Kansas manufacturing plant was forced to shut down after unusually high sodium levels in the Kansas River led to increased salinity in city water. Conductivity of the city water also increased from 500 µS/cm to 1,600 µS/cm. This heightened water conductivity was problematic

…

Read MoreCustomized RO improves long-term safety, efficiency

Problem

An outdated deionization (DI) system in the paint-booth area of an Ohio automotive plant was failing to produce an acceptable quality of water and necessitated excessive chemical costs to meet approved throughput levels. Additionally, chemical leakage was causing damage to floors,

…

Read More